LIFTING AND TRANSPORT SYSTEMS

Lifting and transport systems are essential components of industrial operations, providing the means to move heavy loads, materials, and equipment efficiently and safely.

These systems are vital in industries such as construction, manufacturing, warehousing, and logistics, where the handling and transportation of large or bulky items are a regular part of the workflow. Lifting systems include cranes, hoists, and elevators, while transport systems encompass conveyors, forklifts, and automated guided vehicles (AGVs). Together, these solutions enable companies to optimize material flow, reduce manual labor, and improve overall operational efficiency.

#LiftingSystems #TransportSolutions #MaterialHandling #LiftingEquipment #IndustrialTransport #CraneSystems #ForkliftSolutions #LoadLifting #HeavyLifting #ConveyorSystems #LogisticsSolutions #WarehouseAutomation #CargoHandling #HoistingEquipment #IndustrialLifting #TransportMachinery #AutomatedTransport #LiftingTechnology #SafeLifting #EfficientTransport #MaterialLifting #CustomLiftingSolutions #LiftingAndTransport #HeavyDutyTransport #IndustrialLogistics #LiftingAndMoving #TransportEngineering #LoadTransport #HighCapacityLifting #LiftAndMove

Key Components of Lifting and Transport Systems

Cranes and Hoists

- Overview: Cranes and hoists are fundamental lifting solutions designed to handle heavy loads in vertical and horizontal directions. Overhead cranes, gantry cranes, and jib cranes are commonly used in factories, shipyards, and construction sites, while hoists are used to lift loads vertically with precision.

- Applications: Cranes and hoists are often used in manufacturing plants to move large machinery, in construction for placing heavy materials, and in warehouses for loading and unloading goods.

Conveyor Systems

- Overview: Conveyor systems are used to transport materials along a fixed path, often over long distances or between different levels. Belt conveyors, roller conveyors, and chain conveyors are the most common types. They offer continuous, automated movement of products or materials, reducing manual handling and increasing throughput.

- Applications: Industries such as mining, automotive manufacturing, and food processing utilize conveyor systems to move bulk materials, components, and finished products efficiently.

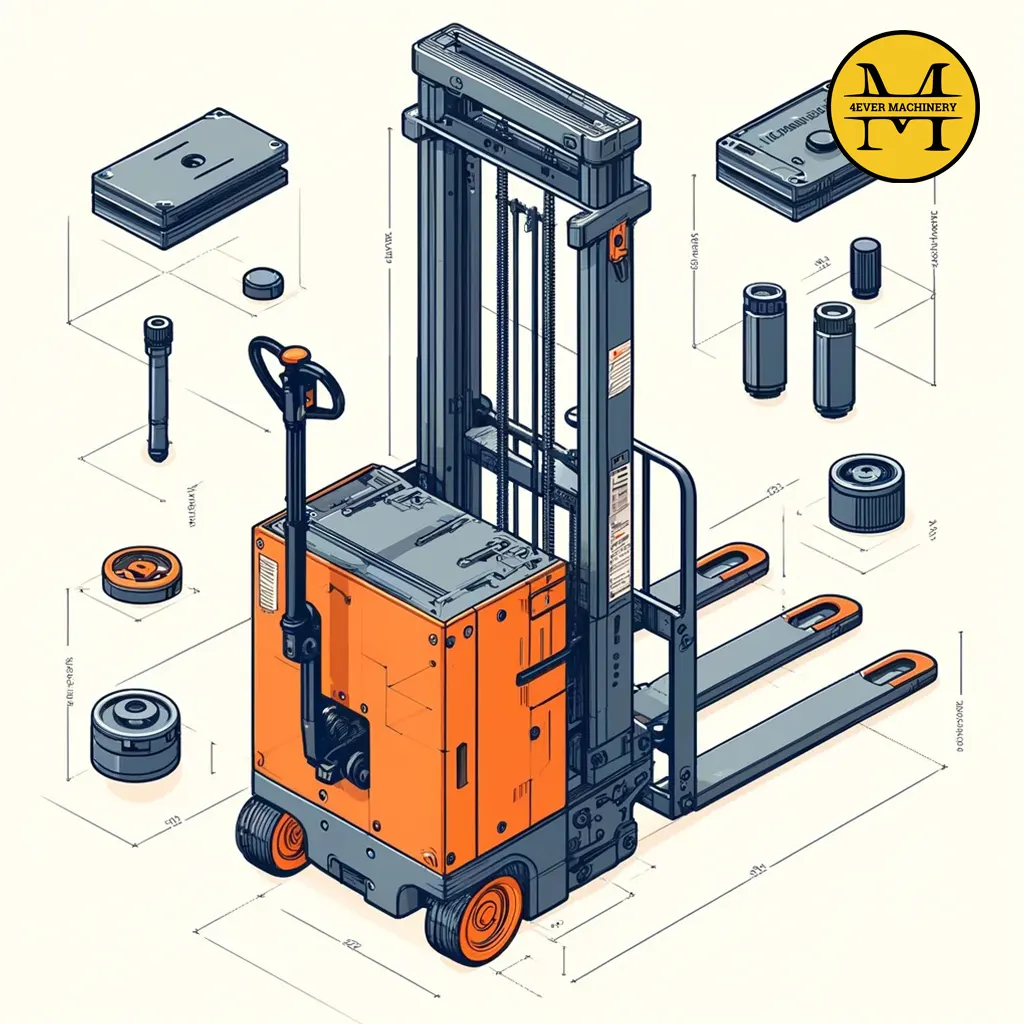

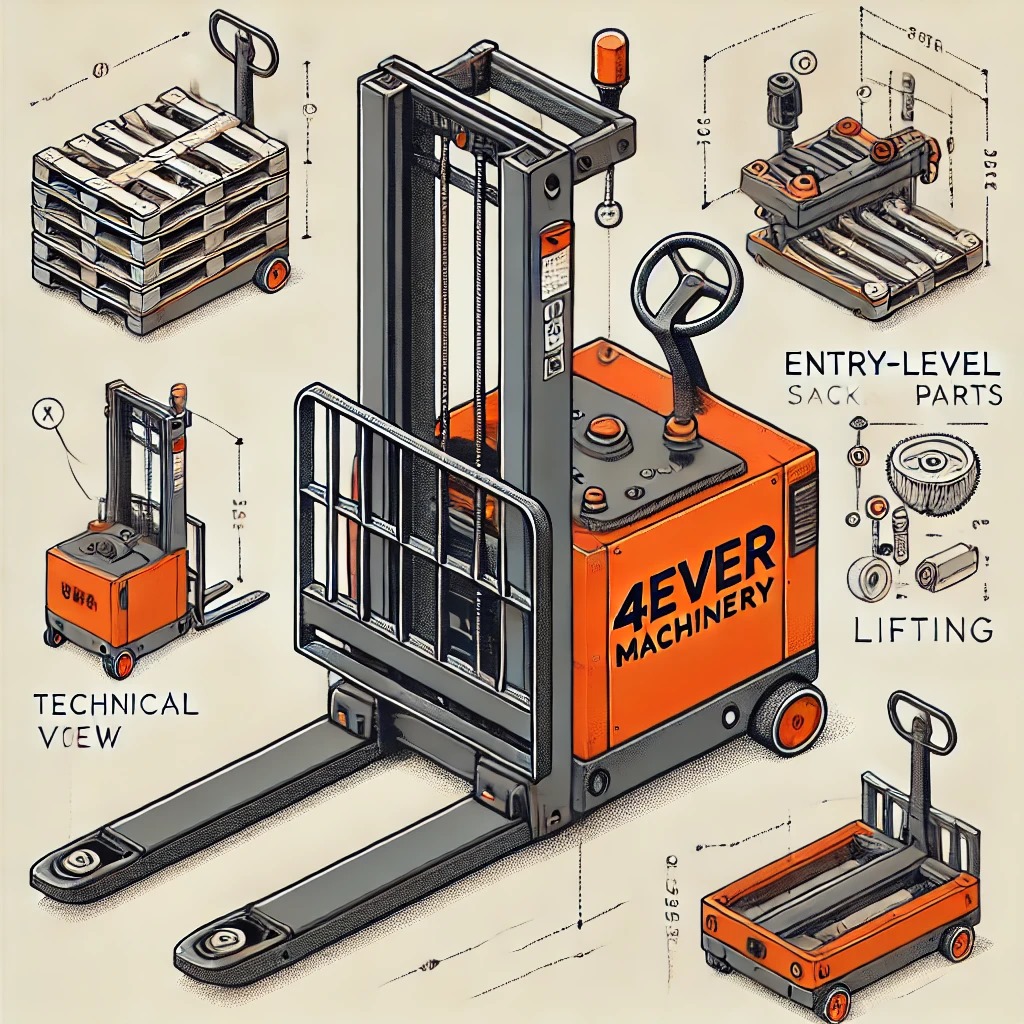

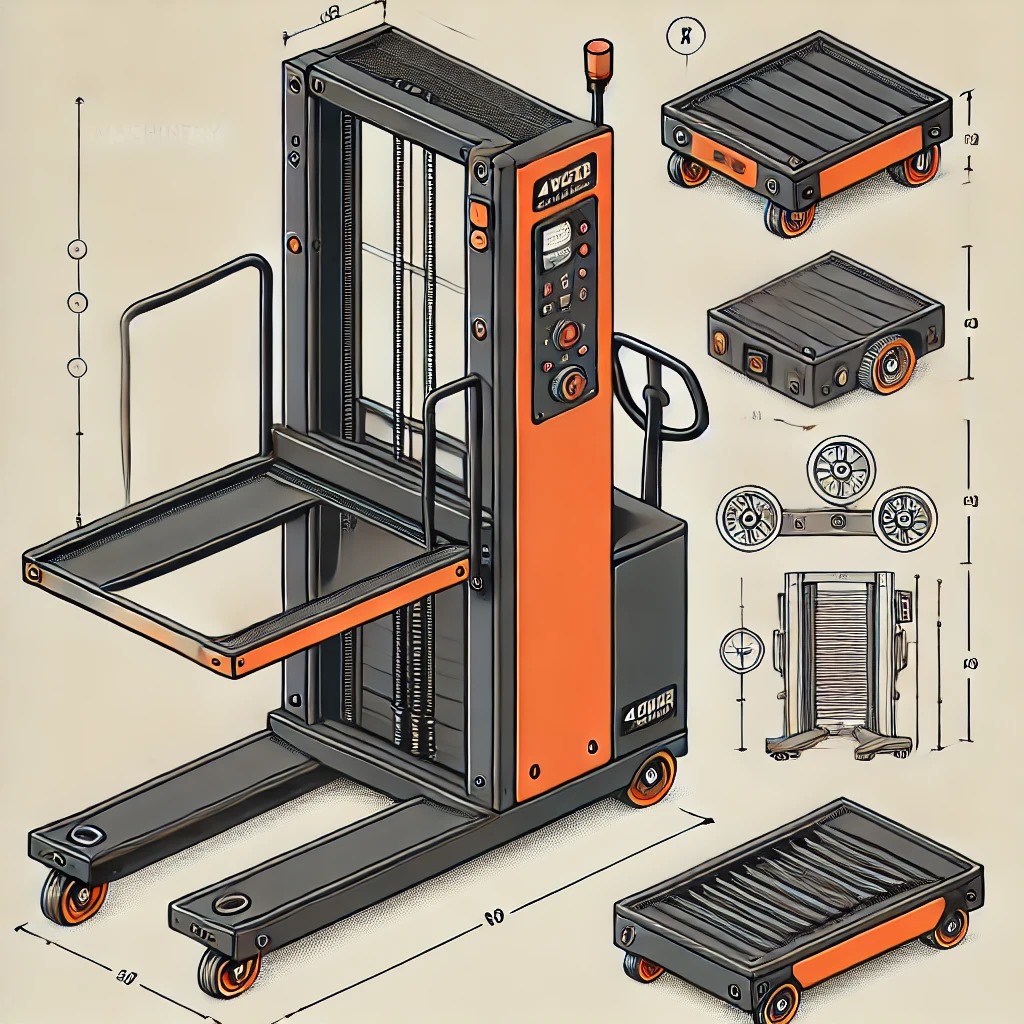

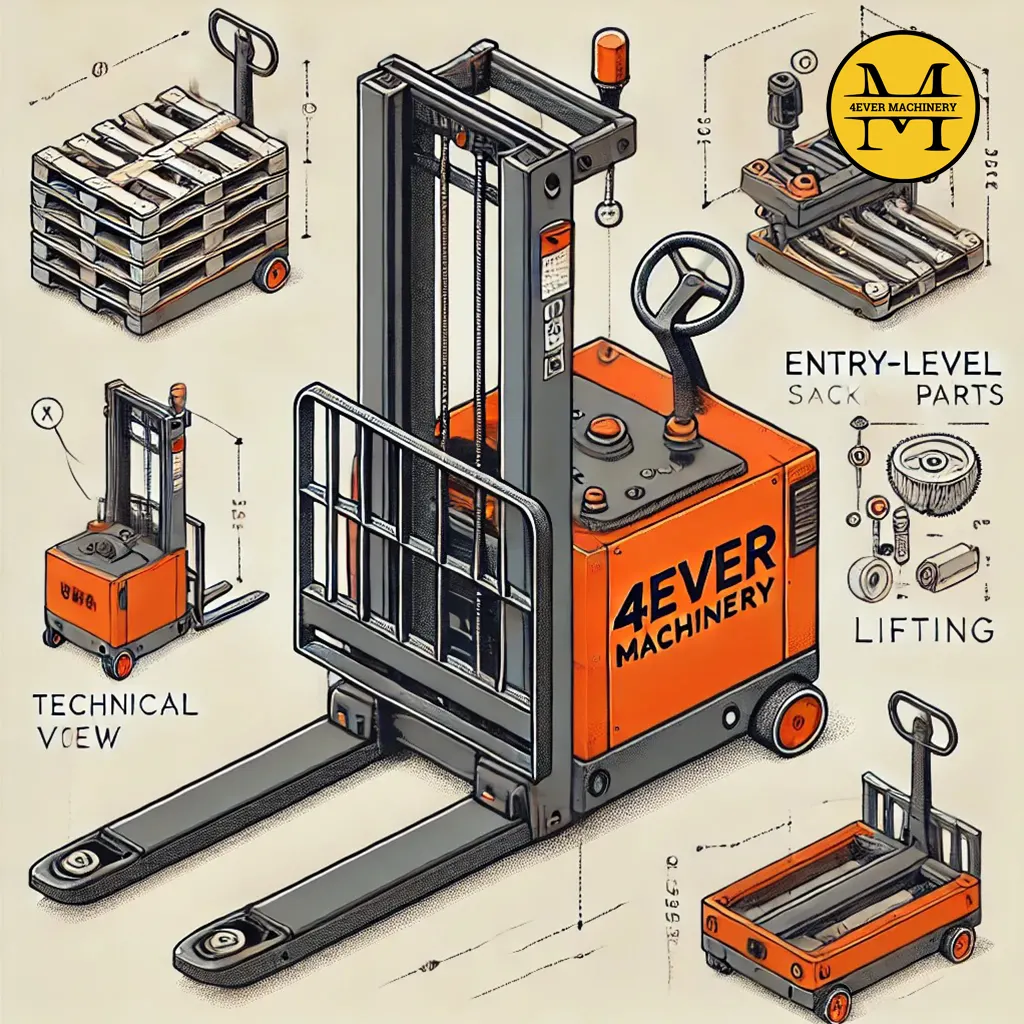

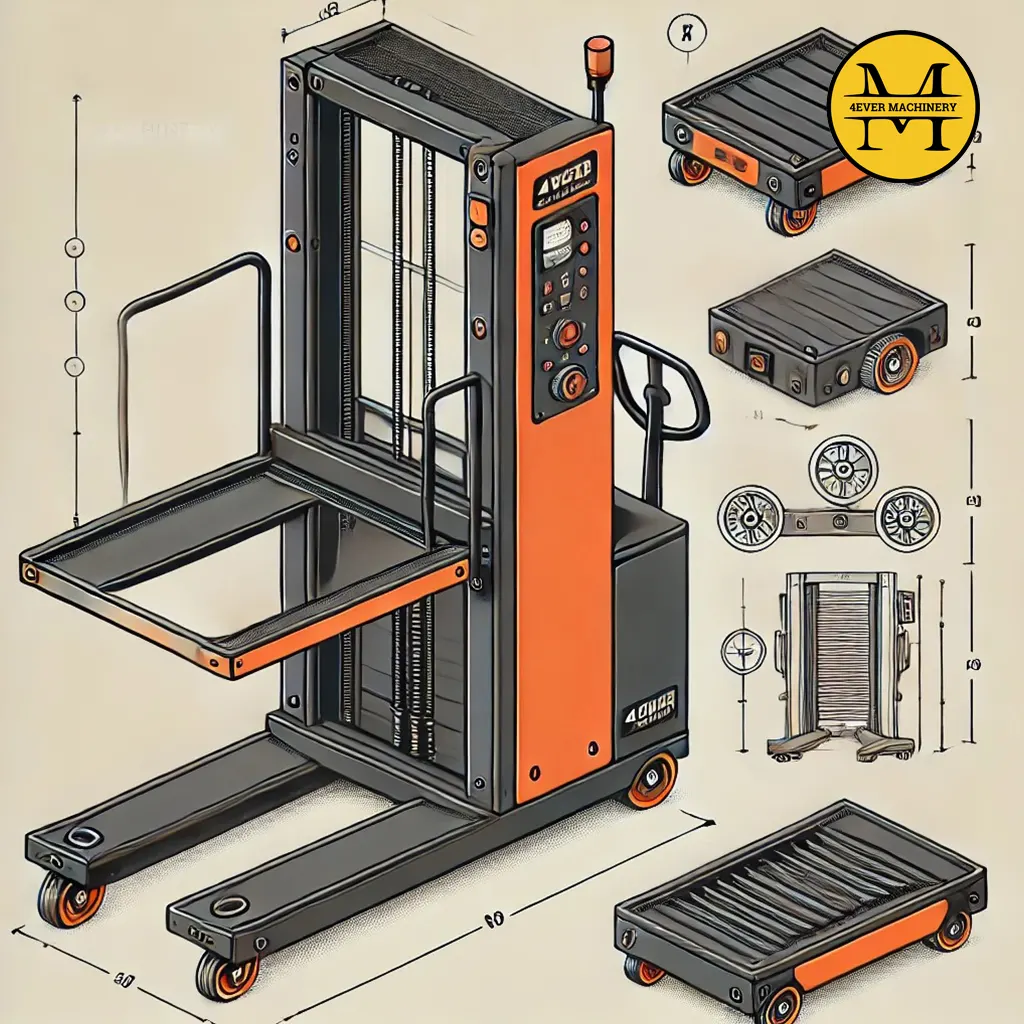

Forklifts and Industrial Trucks

- Overview: Forklifts and industrial trucks are essential for material handling and transport in warehouses, manufacturing plants, and loading docks. These vehicles can lift, carry, and transport heavy loads across different areas within a facility, ensuring smooth material flow.

- Applications: Forklifts are indispensable in logistics and warehousing for stacking pallets, loading and unloading trucks, and moving materials around production lines.

Automated Guided Vehicles (AGVs)

- Overview: AGVs are a critical part of modern transport systems, providing automated, driverless transportation of goods within factories, warehouses, and distribution centers. AGVs use sensors, cameras, and software to navigate predefined paths, offering increased efficiency, precision, and safety in material handling.

- Applications: AGVs are commonly employed in automotive manufacturing, electronics assembly, and e-commerce warehouses to handle repetitive tasks like material transport and product assembly.

Elevators and Lifts

- Overview: Elevators and lifts are used in both industrial and commercial settings to move goods and personnel between different floors or levels. Industrial lifts, such as scissor lifts and platform lifts, are designed for heavy-duty use in factories, warehouses, and construction sites.

- Applications: Industrial elevators are essential for multi-level warehouses, construction projects, and manufacturing facilities where vertical transportation of heavy equipment or goods is required.

Advancements in Lifting and Transport Systems

Automation and Digital Control

- Overview: Automation is transforming the landscape of lifting and transport systems. Cranes, hoists, and AGVs are increasingly equipped with automated control systems, allowing for precise movements and enhanced safety through remote operation and monitoring.

- Benefits: Automation reduces the need for manual intervention, minimizes human error, and increases overall operational efficiency.

Enhanced Safety Features

- Overview: Modern lifting and transport systems come equipped with advanced safety features, including overload protection, anti-collision technology, and real-time monitoring systems that alert operators to potential hazards.

- Benefits: These innovations greatly reduce the risk of accidents, equipment damage, and injuries in industrial environments.

Energy Efficiency and Sustainability

- Overview: Energy-efficient designs and sustainable technologies are becoming more prevalent in lifting and transport systems. Electric-powered forklifts, regenerative braking systems in cranes, and energy-efficient conveyors help reduce power consumption and lower the carbon footprint of industrial operations.

- Benefits: Adopting energy-efficient systems leads to cost savings, improved operational sustainability, and compliance with environmental regulations.

Customizable and Modular Designs

- Overview: Many lifting and transport systems are now available in modular and customizable configurations, allowing companies to tailor their equipment to the specific needs of their operations. This flexibility ensures that systems can be adapted to unique material handling requirements, space constraints, and production flows.

- Benefits: Modular systems offer scalability, ease of maintenance, and the ability to upgrade or expand as operational needs evolve.

Industry Applications

Construction and Infrastructure

- Overview: Lifting systems are critical in construction projects for moving materials like steel beams, concrete, and equipment to various heights and locations. Cranes and hoists play a crucial role in ensuring timely completion of projects by facilitating the safe and efficient movement of heavy loads.

Manufacturing

- Overview: In manufacturing plants, lifting and transport systems are essential for moving raw materials, parts, and finished goods through different stages of the production line. Conveyor systems, AGVs, and forklifts ensure the smooth flow of materials, optimizing production efficiency and reducing downtime.

Warehousing and Logistics

- Overview: In warehousing and logistics, lifting systems like forklifts and automated lifts help organize and move goods for storage, order picking, and shipping. AGVs and conveyor systems are crucial for streamlining processes in large distribution centers.

Mining and Heavy Industry

- Overview: In mining and heavy industry, lifting and transport systems handle some of the most challenging materials, including ores, rocks, and heavy machinery. Specialized cranes, conveyors, and industrial trucks are designed to withstand extreme conditions and handle the bulk material loads common in these industries.

Conclusion

Lifting and transport systems are the backbone of material handling in many industries, providing the tools necessary to move heavy loads with precision, efficiency, and safety. From automated AGVs in modern factories to cranes and hoists in construction, these systems ensure that materials flow smoothly and operations run efficiently. As technology continues to evolve, advancements in automation, safety, and energy efficiency will further enhance the capabilities of lifting and transport systems.

4Ever Machinery delivers innovative and tailored lifting and transport solutions, designed to meet the specific needs of industries ranging from manufacturing to construction. Our systems are engineered for maximum performance, reliability, and safety, ensuring that your material handling processes are optimized for success.