DEFENSE INDUSTRY SOLUTIONS

The defense industry demands precision, reliability, and innovation at every stage of production. Companies that manufacture defense-related products, whether for military vehicles, equipment, or advanced weaponry, require robust and highly specialized industrial systems.

At 4Ever Machinery, we don’t produce defense products directly, but we offer comprehensive industrial manufacturing solutions that help defense contractors optimize their production processes. We design and implement advanced production systems that ensure efficiency, precision, and adherence to the stringent quality and safety standards of the defense sector.

#DefenseIndustry #MilitarySolutions #DefenseTechnology #SecuritySolutions #MilitaryEngineering #DefenseManufacturing #DefenseContracting #AdvancedDefense #MilitaryEquipment #DefenseInnovation #DefenseSystems #SecurityEngineering #MilitaryLogistics #DefenseProcurement #MilitaryTech #DefenseStrategy #WeaponSystems #TacticalSolutions #CyberDefense #DefenseReadiness #DefenseResearch #ArmamentSystems #MilitarySupport #NationalSecurity #DefenseInfrastructure #DefenseContractors #AdvancedManufacturing #DefensePartnerships #AerospaceAndDefense #MilitaryIndustrialComplex

Custom Production Planning

- Overview: Defense industry manufacturing is highly specialized and often involves complex assembly processes for sensitive components. We offer custom production planning services that map out the entire manufacturing process, from material handling to final assembly. Our solutions are tailored to meet the unique needs of defense manufacturers, ensuring a seamless workflow from start to finish.

- Applications: Production planning is essential for manufacturers producing military vehicles, electronics, or weapon systems, where precision and efficiency are critical.

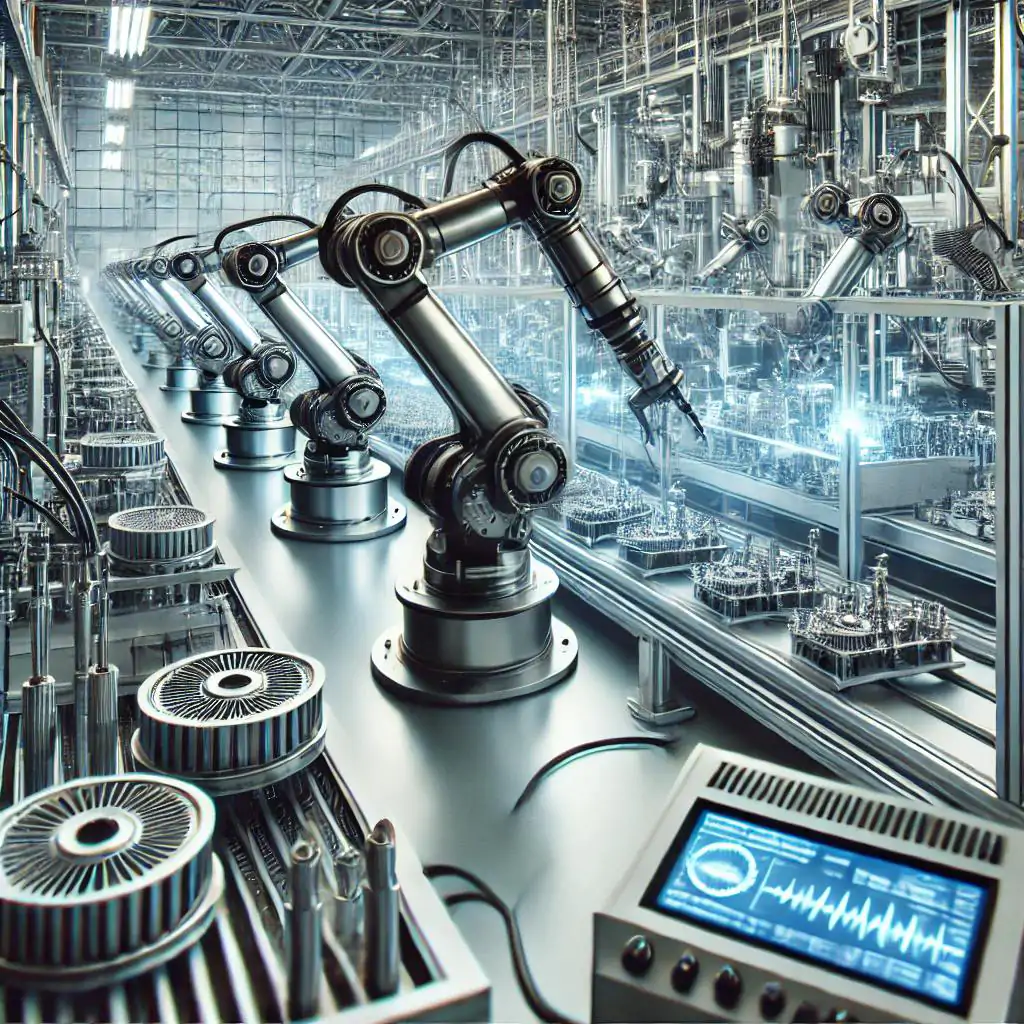

Automation for Precision and Consistency

- Overview: Automation plays a key role in meeting the high standards of defense product manufacturing. Our automated systems are designed to handle tasks such as welding, component assembly, and surface treatment with absolute precision. By integrating advanced robotics and control systems, we ensure that each product meets exact specifications and is produced consistently across large production runs.

- Applications: Automated systems are used for assembling military electronics, welding vehicle armor, and fabricating high-tolerance components used in defense products.

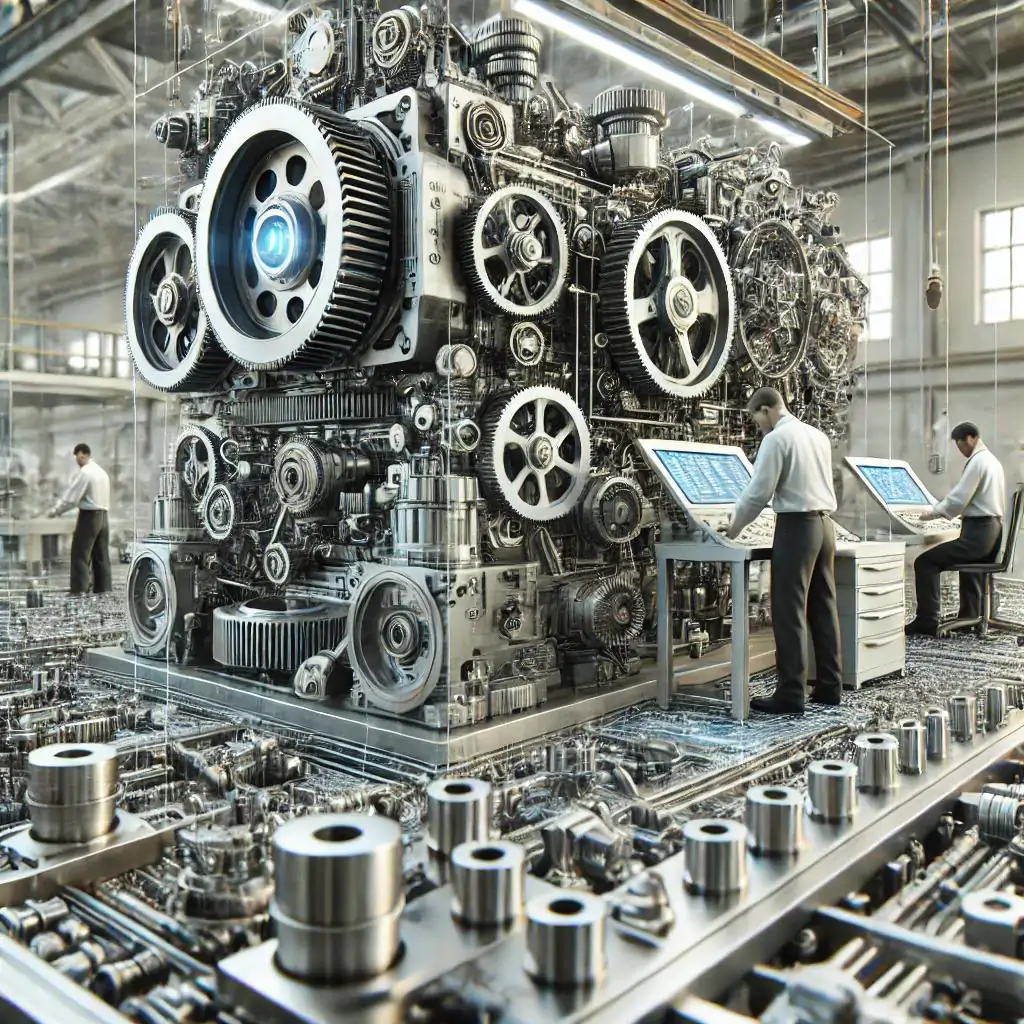

Precision Machining and Fabrication

- Overview: Precision is paramount in the defense industry, where even the slightest error can have significant consequences. We provide precision machining solutions that meet the exacting requirements of defense contractors, whether for weapon systems, military-grade vehicles, or advanced communication equipment. Our machining systems are designed for high accuracy, ensuring that all components meet rigorous military specifications.

- Applications: Precision machining is vital for producing critical components such as firearm barrels, vehicle chassis, and intricate electronic systems.

Advanced Material Handling and Transport Systems

- Overview: Efficient material handling is crucial in the defense manufacturing process, where heavy and delicate components often need to be transported across different stages of production. We offer advanced material handling systems, including automated guided vehicles (AGVs) and conveyor systems, that ensure the safe and efficient transport of materials and finished products throughout the manufacturing facility.

- Applications: These systems are used in factories producing military vehicles, aircraft components, and large-scale defense equipment.

Advancements in Defense Industry Manufacturing

Smart Manufacturing and Industry 4.0

- Overview: The integration of smart technologies is transforming the defense industry. By incorporating IoT (Internet of Things) sensors, real-time monitoring, and data analytics into manufacturing systems, we offer defense manufacturers greater control and insight into their production processes. These systems enable predictive maintenance, real-time quality checks, and continuous process optimization, ensuring that production remains efficient and error-free.

- Benefits: Real-time monitoring and data analytics improve overall production quality and reduce downtime by predicting and addressing maintenance issues before they cause delays.

Sustainability and Energy Efficiency

- Overview: As defense manufacturers look to reduce their environmental impact, we offer energy-efficient machinery and sustainable production systems that minimize waste, emissions, and energy consumption. Our solutions allow manufacturers to maintain high output while meeting environmental regulations.

- Benefits: Sustainable manufacturing reduces operational costs, meets regulatory standards, and enhances a company’s reputation in both defense and environmental circles.

Modular and Scalable Systems

- Overview: Defense manufacturing often requires flexibility to adapt to new projects, changing product designs, or varying production volumes. We design modular and scalable production systems that allow manufacturers to quickly adjust their setups to meet new demands. Whether scaling up production for a large defense contract or modifying processes for a new product line, our systems provide the agility manufacturers need to remain competitive.

- Benefits: Modular systems can be reconfigured easily, making them ideal for manufacturers dealing with fluctuating production demands or new defense contracts.

Industry Applications

Military Vehicle Manufacturing

- Overview: The production of military vehicles, from armored personnel carriers to tanks, requires specialized manufacturing systems capable of handling large, heavy components with precision. We offer complete production systems for welding, machining, and assembling military vehicles, ensuring durability and performance in combat conditions.

- Benefits: Our solutions guarantee high production accuracy, ensuring that vehicles meet the stringent safety and operational standards required for defense applications.

Weapon Systems and Components

- Overview: Manufacturing weapon systems demands exacting precision and strict quality control. Our production systems are tailored to meet the unique requirements of defense contractors producing firearms, ammunition, and advanced weapon systems. From precision machining to component assembly, our solutions ensure that every product meets the necessary military standards.

- Benefits: High-precision manufacturing reduces the risk of errors and improves the overall quality of weapon systems and components.

Military-Grade Electronics Manufacturing

- Overview: The production of military-grade electronics, such as communication systems, radar, and defense control systems, requires advanced automation and precision assembly. We offer specialized production systems for assembling and testing these complex electronic components, ensuring their reliability and performance in critical defense applications.

- Benefits: Our systems enhance the precision and efficiency of electronics manufacturing, ensuring that all components meet stringent defense standards.

Conclusion

In the defense industry, where precision, reliability, and adaptability are key, 4Ever Machinery provides the advanced manufacturing solutions necessary to meet these challenges. Our custom production planning, automation systems, and precision machining capabilities enable defense contractors to optimize their production processes while ensuring the highest levels of quality and safety. By integrating the latest in smart manufacturing, sustainability, and modular design, we empower defense manufacturers to meet the complex demands of their industry.

4Ever Machinery is committed to helping defense manufacturers streamline their operations, increase production efficiency, and deliver top-tier products that meet the stringent requirements of the defense industry.