INDUSTRIAL SOLUTIONS

Industrial solutions encompass a wide range of technologies, services, and systems designed to optimize and improve the performance of industrial operations.

These solutions are tailored to address specific challenges within industries such as manufacturing, energy, automotive, aerospace, and construction. From automation and control systems to custom machinery, material handling, and advanced production techniques, industrial solutions aim to enhance efficiency, reduce costs, and ensure safety while meeting the ever-evolving demands of global markets.

#IndustrialSolutions #IndustrialAutomation #SmartManufacturing #Industry40 #IndustrialEngineering #CustomIndustrialSystems #ManufacturingSolutions #IndustrialInnovation #AutomationSolutions #IndustrialEquipment #ProductionOptimization #FactoryAutomation #IndustrialDesign #ProcessAutomation #IndustrialEfficiency #SmartFactories #IndustrialAutomationSystems #IndustrialMachinery #AdvancedManufacturing #IndustrialTechnology #CustomEngineeringSolutions #ManufacturingExcellence #EngineeringInnovation #ModularManufacturing #TurnkeyIndustrialSolutions #AutomatedSystems #PrecisionEngineering #IndustrialManufacturing #EfficientProduction #InnovativeIndustrialSolutions

Key Components of Industrial Solutions

Automation and Control Systems

- Overview: Automation is at the heart of modern industrial solutions, allowing manufacturers to streamline operations, increase productivity, and reduce human error. Automation systems, such as programmable logic controllers (PLCs), robotics, and supervisory control and data acquisition (SCADA) systems, are widely used to monitor, control, and optimize production lines.

- Applications: Automation plays a crucial role in industries like automotive manufacturing, chemical processing, and packaging, enabling continuous production with minimal downtime.

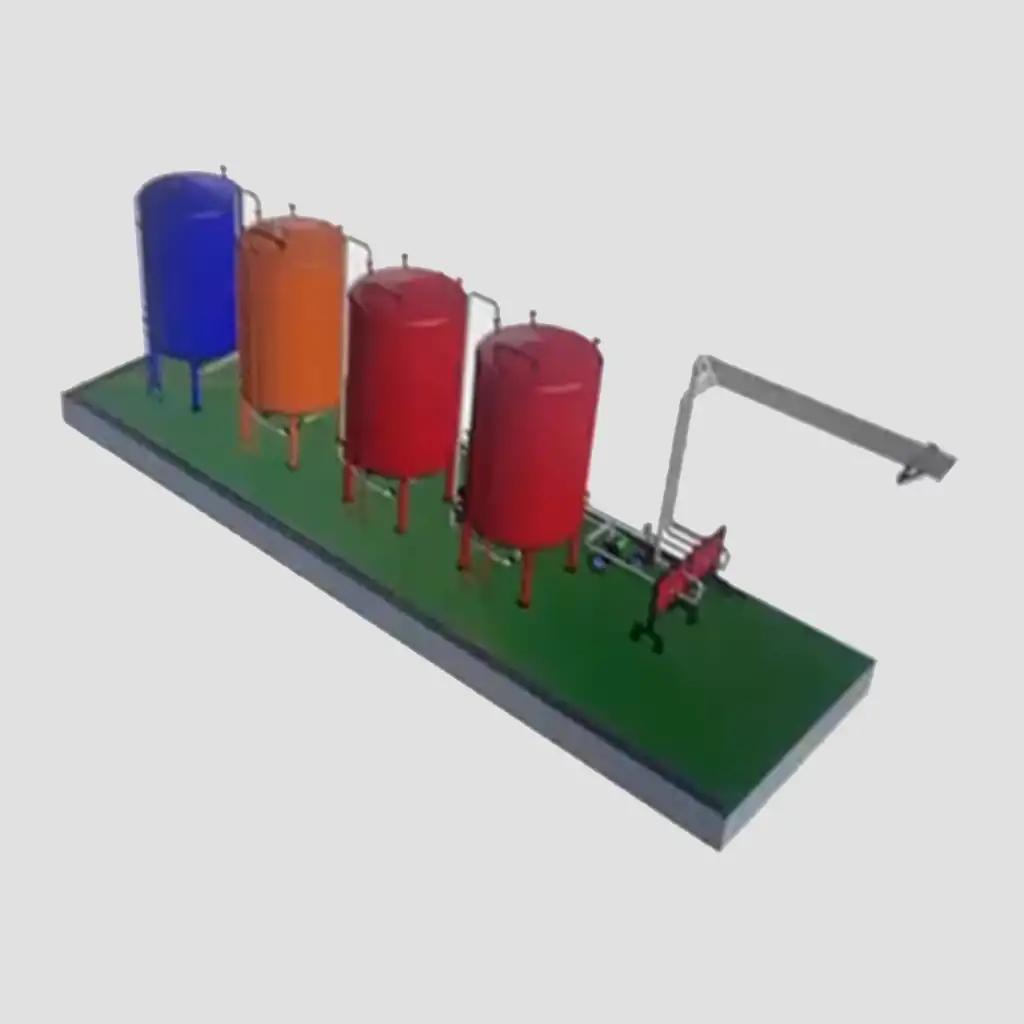

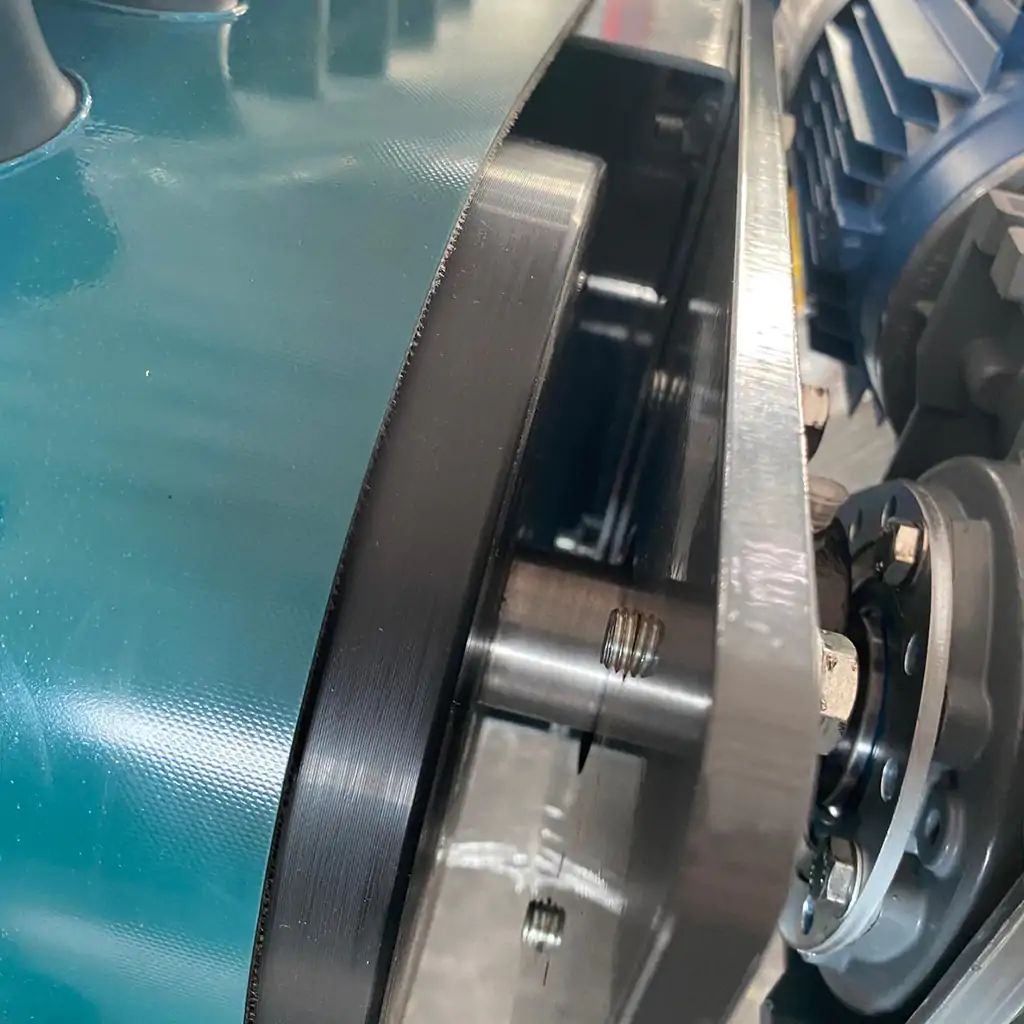

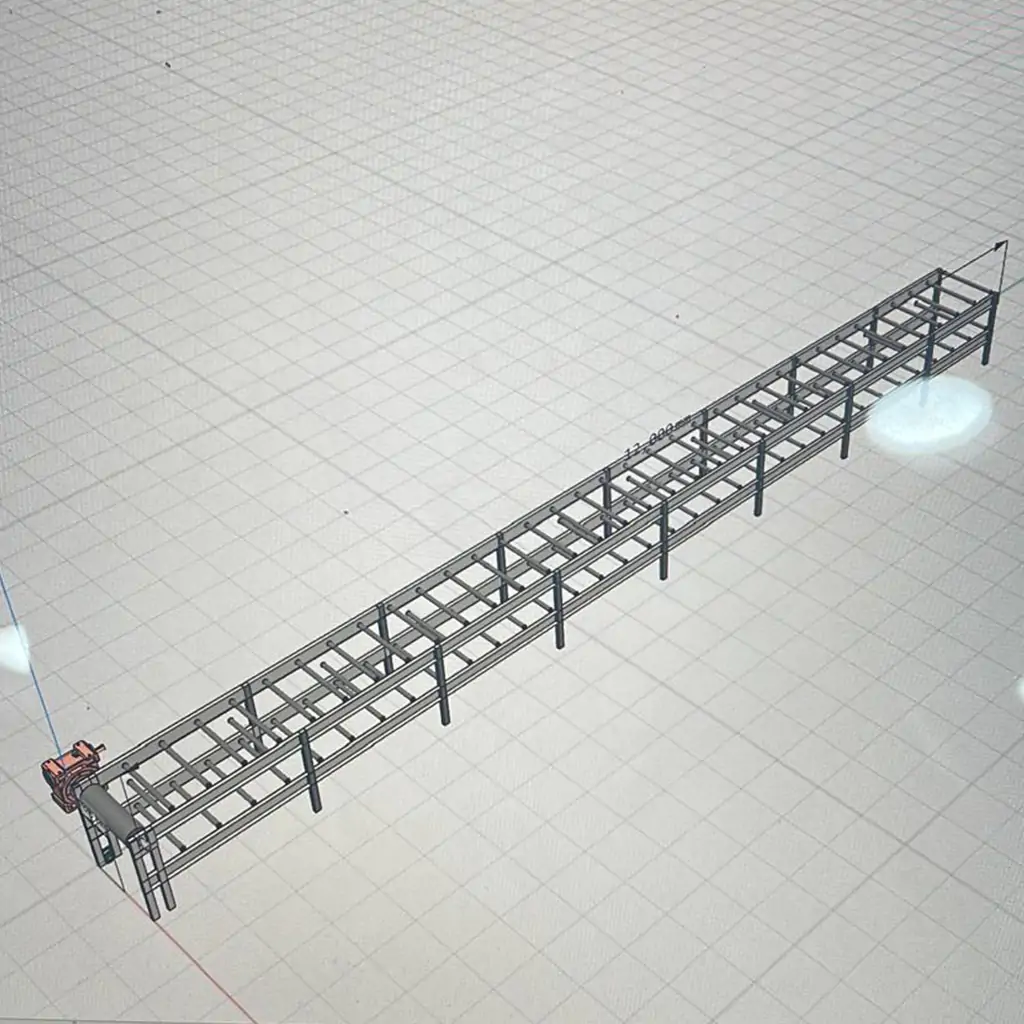

Custom Machinery and Equipment

- Overview: Many industries require specialized machinery to perform specific tasks or handle unique materials. Custom machinery solutions are designed to meet the exact needs of each production process, whether it’s a high-precision milling machine or a custom conveyor system.

- Applications: Custom machinery is often employed in niche sectors such as aerospace, food processing, and pharmaceutical manufacturing, where standard equipment may not meet strict regulatory requirements or performance standards.

Material Handling Systems

- Overview: Efficient material handling is essential for ensuring smooth production workflows, reducing bottlenecks, and maintaining consistent output. Industrial solutions include conveyor systems, automated guided vehicles (AGVs), and storage solutions to facilitate the movement and storage of raw materials and finished products.

- Applications: Industries such as logistics, warehousing, and large-scale manufacturing benefit from optimized material handling systems, improving throughput and minimizing damage to products during transit.

Energy Management and Sustainability Solutions

- Overview: As industries face increasing pressure to reduce their environmental impact, energy management solutions have become a crucial part of industrial operations. These solutions involve the use of energy-efficient technologies, waste reduction strategies, and renewable energy integration to optimize energy consumption.

- Applications: Sectors like heavy manufacturing, chemical production, and power generation rely on energy management systems to minimize costs and meet regulatory standards for emissions and energy use.

Maintenance and Predictive Analytics

- Overview: Maintenance is a critical aspect of industrial solutions. Preventive and predictive maintenance systems help reduce unplanned downtime by monitoring equipment health and predicting potential failures before they occur. This is achieved through data collection, sensors, and advanced analytics that provide real-time insights into machine performance.

- Applications: Predictive maintenance is widely used in industries with high-value machinery, such as oil and gas, aerospace, and industrial machinery manufacturing, to extend equipment life and minimize costly repairs.

Advancements in Industrial Solutions

Digitalization and Industry 4.0

- Overview: The integration of digital technologies into industrial solutions, known as Industry 4.0, has revolutionized production processes. With technologies like the Internet of Things (IoT), artificial intelligence (AI), and big data analytics, companies can now monitor and optimize every aspect of their operations in real-time.

- Benefits: Digitalization allows for smarter decision-making, predictive maintenance, improved product quality, and reduced production costs.

Robotics and AI Integration

- Overview: Robotics and AI are increasingly being integrated into industrial solutions to automate complex tasks, reduce labor costs, and improve precision. These systems can handle intricate operations, such as assembly, inspection, and packaging, with a high degree of accuracy.

- Benefits: The use of AI and robotics in industrial solutions leads to faster production times, increased safety, and reduced reliance on manual labor.

Sustainability and Green Manufacturing

- Overview: The growing demand for sustainable solutions is driving innovation in energy-efficient processes, waste reduction, and green manufacturing practices. Industrial solutions now focus on reducing carbon footprints, using renewable energy sources, and implementing circular economy practices.

- Benefits: Sustainable industrial solutions not only contribute to environmental conservation but also offer long-term cost savings through improved energy efficiency and reduced waste.

Industry Applications

- Automotive

- Overview: The automotive industry relies heavily on automation, robotics, and precision engineering to produce vehicles efficiently. Industrial solutions in this sector include assembly line automation, robotic welding, and advanced quality control systems.

- Energy and Power

- Overview: In the energy sector, industrial solutions help optimize power generation, distribution, and consumption. Solutions like smart grids, renewable energy integration, and energy storage systems are transforming how energy is managed.

- Aerospace

- Overview: Aerospace companies use industrial solutions to manufacture aircraft components with extreme precision and reliability. These solutions include custom machining, 3D printing for lightweight materials, and automated inspection systems.

Conclusion

Industrial solutions provide the foundation for modern manufacturing and production processes, enabling industries to meet the demands of efficiency, safety, and sustainability. Whether through automation, custom machinery, or energy management, these solutions are essential for driving progress in global industries. As new technologies continue to emerge, industrial solutions will become even more integrated, efficient, and eco-friendly, shaping the future of production.

4Ever Machinery is at the forefront of delivering advanced industrial solutions, offering custom equipment and systems that meet the unique demands of various sectors. By integrating the latest technologies, we help companies achieve greater efficiency, reliability, and sustainability in their operations.