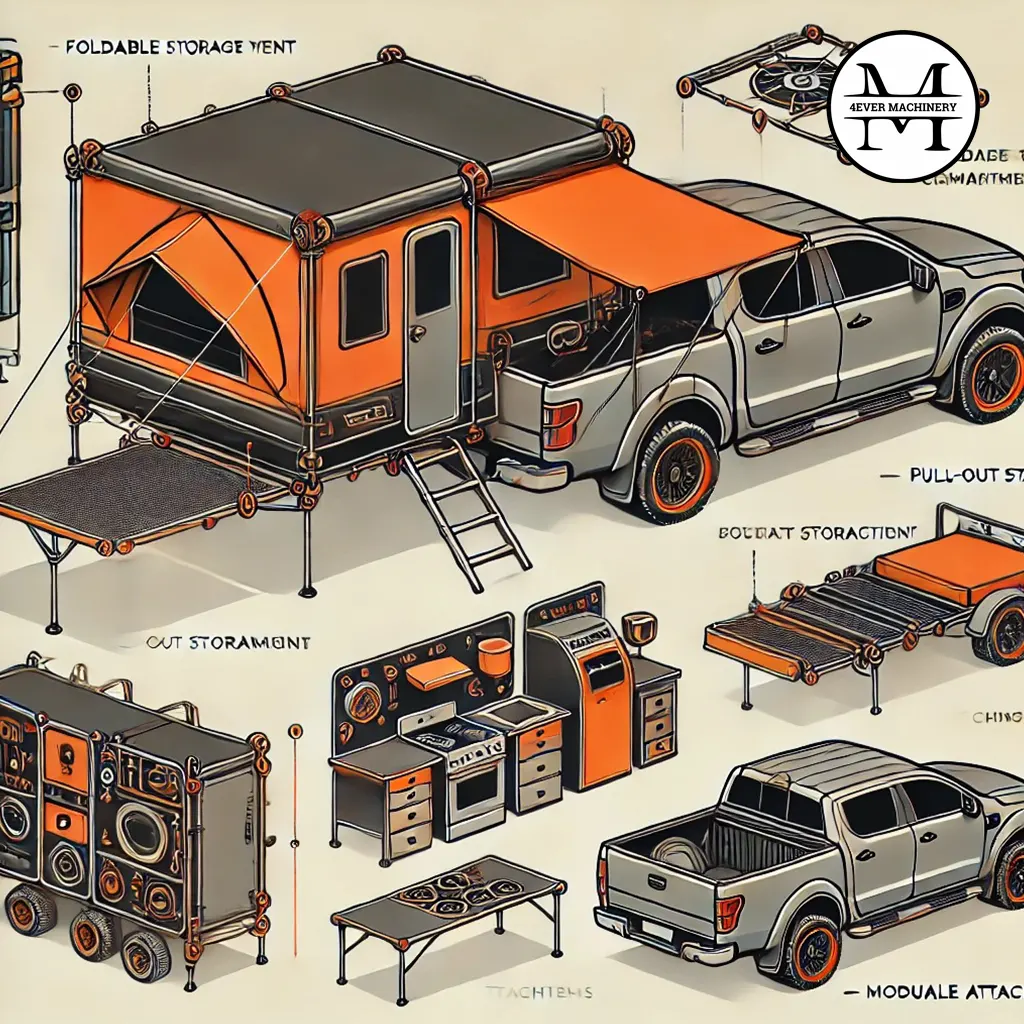

PICKUP AND CAMPING EQUIPMENT MANUFACTURING SYSTEMS

The pickup and camping equipment industry relies on specialized production processes to meet the growing demands of outdoor enthusiasts and professionals alike. Whether it’s manufacturing heavy-duty pickup accessories, rooftop tents, or camping gear, the right production systems play a pivotal role in ensuring quality and efficiency.

At 4Ever Machinery, we don’t produce these products directly, but we design and implement the advanced machinery and automation systems that power their production. Our solutions help manufacturers streamline their workflows, increase productivity, and maintain consistent quality across every item.

#PickupEquipment #CampingGear #OutdoorManufacturing #CampingEquipment #TruckAccessories #OffRoadCamping #CustomCampingSolutions #ManufacturingOutdoorGear #AdventureGear #CampingLife #PickupTruckAccessories #ManufacturingSystems #OutdoorEquipment #CampingInnovation #PickupSolutions #CampingManufacturing #HeavyDutyCamping #TruckCamping #EcoFriendlyCamping #PortableCamping #OutdoorAdventureGear #PickupCustomization #ManufacturingAdventure #CampingSystemDesign #AllTerrainCamping #CampingEssentials #TruckLife #OutdoorManufacturers #CampingSolutions #ManufacturingExcellence

Key Components of Pickup and Camping Equipment Manufacturing Systems

Custom Production Lines

- Overview: Manufacturing pickup accessories like bed liners, truck caps, or heavy-duty roof racks requires customized production lines that can handle metal fabrication, assembly, and coating. We design tailor-made production systems that meet the specific requirements of these products, ensuring smooth processes from start to finish.

- Applications: These custom lines are used for the precise cutting, welding, and coating of metal parts for pickups and camping equipment, ensuring accuracy and durability.

Automation in Component Production

- Overview: Automating key production stages is essential for manufacturers looking to improve efficiency. From metal stamping and cutting to welding and final assembly, automation can dramatically reduce production time and minimize errors. We specialize in creating automated systems that integrate seamlessly with existing workflows, enhancing productivity.

- Applications: Automated welding, metal forming, and assembly stations for truck-mounted camping gear such as roof tents, awnings, or utility boxes improve production speed and consistency.

Precision Machining for High-Quality Components

- Overview: Pickup and camping equipment often involves complex components requiring high precision. Whether it’s a specialized hitch system or a heavy-duty roof rack, our precision machining solutions ensure each part meets exact specifications, critical for products that must endure rugged outdoor conditions.

- Applications: Precision machining is vital for producing hitch systems, load-bearing components, and other critical parts that demand high tolerances and strength.

Flexible and Modular Production Systems

- Overview: As product designs evolve, manufacturing systems must be able to adapt. We offer flexible, modular systems that can be reconfigured to accommodate new product lines or design changes, giving manufacturers the agility to respond to market trends and consumer demands.

- Applications: Modular systems are perfect for manufacturers that need to switch between producing different pickup accessories, such as roof racks, cargo systems, or slide-out kitchen units for camping.

Advancements in Pickup and Camping Equipment Manufacturing

Advanced Robotics and Automation

- Overview: Robotics is revolutionizing manufacturing by increasing speed, precision, and consistency. For the production of pickup accessories and camping equipment, advanced robotics can handle tasks like welding, component assembly, and packaging with minimal human intervention, driving up efficiency while reducing labor costs.

- Benefits: Robotic systems reduce errors, ensure repeatability, and free up human labor for more skilled tasks, improving overall factory output.

Sustainability in Manufacturing

- Overview: Sustainability is a growing concern in the outdoor equipment industry. We design energy-efficient production lines that minimize waste and reduce emissions, allowing manufacturers to meet environmental regulations without sacrificing output quality.

- Benefits: Sustainable production systems not only reduce operational costs but also improve a company’s environmental impact, appealing to eco-conscious consumers.

Smart Manufacturing and Data Analytics

- Overview: In today’s competitive market, manufacturers benefit from real-time data tracking and analytics. By integrating IoT technologies into production systems, we provide real-time monitoring, predictive maintenance, and data-driven insights, allowing manufacturers to optimize their processes continuously.

- Benefits: Real-time data can help identify bottlenecks, predict equipment failures, and improve overall efficiency in production, reducing downtime and increasing throughput.

Custom Machinery for Unique Products

- Overview: Not all products can be made with off-the-shelf machinery. We offer bespoke machine design services, creating custom solutions tailored to the specific requirements of the manufacturer’s product line. Whether it’s for a unique type of truck bed accessory or a modular camping system, we develop machines that fit seamlessly into the production process.

- Benefits: Custom machinery ensures that unique or highly specialized products can be manufactured with precision, improving overall product quality and consistency.

Industry Applications

Pickup Accessories Manufacturing

- Overview: Pickup trucks are commonly used for both work and recreational purposes, and the demand for aftermarket accessories like tonneau covers, bed racks, and off-road bumpers is strong. We design and implement the machinery that automates the production of these items, ensuring they meet safety and durability standards.

- Benefits: Our systems enhance production capacity, reduce lead times, and ensure high levels of accuracy and consistency in products designed for rugged environments.

Camping Equipment Manufacturing

- Overview: Camping gear such as rooftop tents, cargo systems, and portable kitchens require precise manufacturing to ensure functionality and durability. Our production systems ensure the precise cutting, stitching, and assembly of these items, enhancing their usability and long-term performance in outdoor environments.

- Benefits: Automated production systems improve the efficiency and precision of camping gear manufacturing, meeting the high demands of outdoor enthusiasts.

Component Manufacturing

- Overview: Manufacturers often require custom components for pickup accessories and camping equipment. Our precision machining and automation solutions ensure the reliable production of components, whether it’s a specialized bracket for a roof rack or a slide system for a camping trailer.

- Benefits: With precision-engineered components, manufacturers can ensure that their products maintain high standards of quality, durability, and safety.

Conclusion

The production of pickup accessories and camping equipment is a specialized field that demands efficiency, precision, and flexibility. At 4Ever Machinery, we are dedicated to providing the manufacturing solutions that support these industries, helping manufacturers optimize their processes and deliver high-quality products to market. Our advanced automation systems, precision machining capabilities, and custom machinery design services ensure that our clients stay competitive and innovative in the rapidly growing outdoor equipment sector.

4Ever Machinery is committed to helping companies in the pickup and camping equipment industries scale their operations, meet production challenges, and drive innovation through tailored manufacturing solutions.