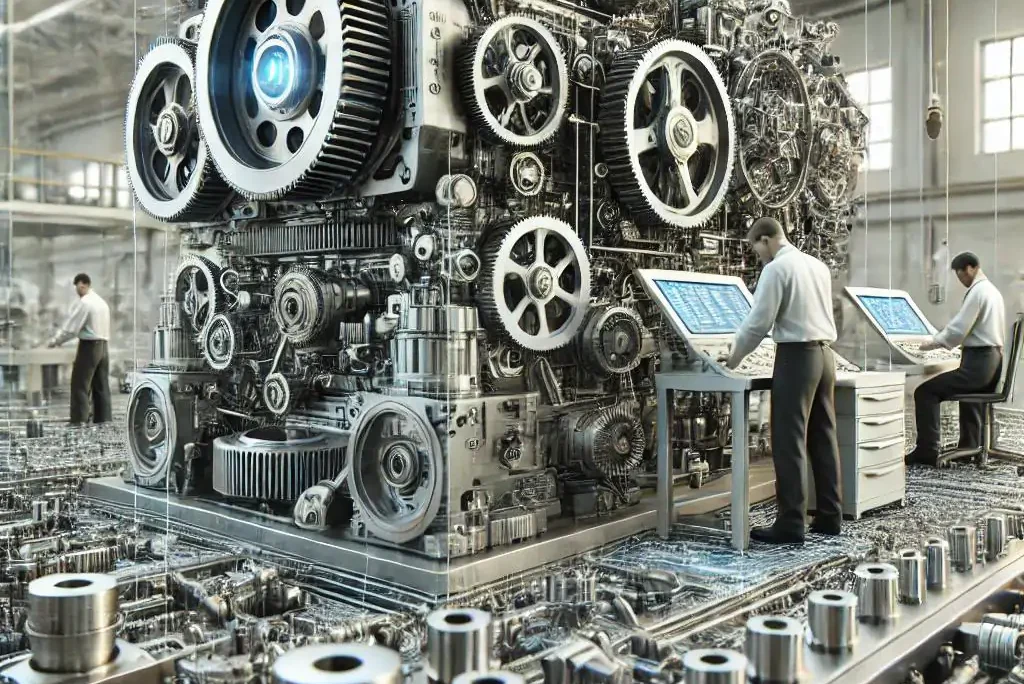

In industries reliant on specialized machinery—such as aerospace, automotive, defense, and heavy manufacturing—the role of custom spare parts is crucial for maintaining seamless operations. Unlike generic parts, custom spare parts are designed to fit the exact specifications of a given piece of equipment, ensuring compatibility, performance, and longevity. As the demands of modern manufacturing and industrial processes evolve, the ability to quickly and precisely produce custom spare parts has become a critical factor for minimizing downtime, reducing costs, and extending the life cycle of specialized equipment. This article explores why custom spare parts are vital for specialized machinery, the challenges in their production, and how advanced manufacturing technologies are providing solutions.

The Role of Custom Spare Parts in Specialized Machinery

Specialized machinery is often designed to perform unique tasks that require precise movements, tolerances, and functionality. Such machinery is commonly found in industries where standardization is not always possible due to specific operational needs. The parts that make up this equipment must meet stringent requirements, as even minor deviations can lead to performance issues or complete failure. Custom spare parts play a pivotal role in addressing these needs by:

- Ensuring Compatibility: Unlike generic parts, custom spare parts are manufactured to match the exact specifications of the original components. This ensures that they fit perfectly, preventing issues like misalignment, wear, and excess friction that can occur when using incompatible replacements.

- Maintaining Performance and Efficiency: Specialized machinery often operates under demanding conditions, such as high speeds, pressures, or temperatures. Custom spare parts ensure that machines maintain their intended performance levels, preserving efficiency and productivity.

- Minimizing Downtime: Downtime due to equipment failure can be extremely costly, particularly in industries that rely on continuous production. Having access to custom spare parts means that repairs can be completed more quickly, reducing the time that machinery is out of service.

- Extending Machinery Life Cycle: The availability of custom spare parts allows companies to keep older machinery in service for longer periods. This is particularly important when the original equipment manufacturer (OEM) no longer produces certain parts or when replacing the entire machine would be prohibitively expensive.

Challenges in Producing Custom Spare Parts

While the benefits of custom spare parts are clear, their production presents a range of challenges, especially when dealing with intricate designs, tight tolerances, and hard-to-machine materials. Some of the main challenges include:

- Complex Geometries

- Overview: Many specialized machines require parts with complex geometries that are difficult to replicate without advanced machining techniques.

- Challenge: Traditional manufacturing methods, such as milling or turning, can struggle to achieve the intricate shapes required by some components, especially those with internal channels or complex curves.

- Solution: The use of 5-axis CNC machines and additive manufacturing (3D printing) allows for the precise production of parts with intricate geometries. These technologies enable manufacturers to create complex shapes that would be challenging or impossible to achieve with conventional methods.

- Material Selection

- Overview: Specialized machinery often uses advanced materials like high-strength alloys, ceramics, or composites to achieve specific performance characteristics.

- Challenge: Sourcing and machining these materials can be difficult due to their cost, hardness, or brittleness. Incorrect material handling can lead to failures or suboptimal part performance.

- Solution: Advanced material science and machining techniques, such as laser cutting, electro-discharge machining (EDM), and cryogenic cooling, are used to handle these materials effectively. Engineers can also employ finite element analysis (FEA) to predict how materials will behave under different conditions, ensuring the right material is selected for the job.

- High Precision Requirements

- Overview: Custom spare parts must meet exact specifications, often with tolerances as tight as a few microns, to ensure that they function seamlessly within a larger system.

- Challenge: Achieving such precision requires state-of-the-art machining and inspection tools. Even small deviations can lead to malfunctioning or excessive wear when parts are used in high-performance machinery.

- Solution: Coordinate Measuring Machines (CMM) and laser scanners are used for precision measurement and quality assurance. These tools ensure that each custom part matches the required specifications before it is installed in a machine.

- Lead Times and Production Speed

- Overview: When a machine goes down, quick access to spare parts is essential to get it back up and running. Long lead times for custom parts can extend periods of downtime, impacting productivity.

- Challenge: Producing custom parts often requires design modifications, prototyping, and small-batch production, which can be time-consuming.

- Solution: Additive manufacturing allows for rapid prototyping and short-run production of custom parts, significantly reducing lead times. Additionally, digital twins and reverse engineering techniques can be used to accelerate the design process, allowing manufacturers to quickly recreate parts that are no longer available from the OEM.

Advanced Solutions for Custom Spare Parts Production

The emergence of advanced manufacturing technologies has transformed the way custom spare parts are produced, making the process faster, more accurate, and more cost-effective. Here are some key innovations in this field:

- Additive Manufacturing (3D Printing)

- Overview: Additive manufacturing enables the creation of complex parts by building them layer by layer, using materials such as metals, polymers, and composites.

- Applications: 3D printing is ideal for producing one-off or low-volume parts, making it a perfect solution for custom spare parts that require intricate details or rapid prototyping.

- Benefits: This technology minimizes material waste and allows for the rapid iteration of designs, reducing both costs and lead times.

- Reverse Engineering

- Overview: Reverse engineering involves scanning an existing part to create a 3D model, which can then be used to produce an exact replica or an improved version of the original.

- Applications: It is particularly useful when OEM parts are no longer available, allowing manufacturers to produce custom replacements without having the original design data.

- Benefits: Reverse engineering ensures compatibility with existing equipment and allows for design improvements that can enhance the performance of the spare part.

- Digital Twins

- Overview: A digital twin is a virtual model of a physical part or system that allows engineers to simulate and optimize the production of custom spare parts before they are physically produced.

- Applications: Digital twins can simulate stress tests, heat dissipation, and other operational conditions, ensuring that custom parts will perform as expected when installed.

- Benefits: This technology helps reduce errors during manufacturing, lowers costs by optimizing production processes, and ensures a seamless fit with existing machinery.

The Economic Benefits of Custom Spare Parts

Investing in custom spare parts production can provide long-term economic benefits for companies that rely on specialized machinery. These benefits include:

- Reduced Downtime Costs: With custom parts available on demand, companies can reduce the costs associated with unexpected equipment failures and production delays.

- Lower Inventory Requirements: Instead of stocking a wide range of generic spare parts, companies can produce custom parts as needed, reducing inventory costs and the risk of obsolescence.

- Extended Equipment Life: By enabling older equipment to be repaired rather than replaced, custom spare parts can extend the lifespan of specialized machinery, delaying the need for costly new investments.

- Improved Product Quality: Custom parts can be designed to enhance the performance of existing machinery, resulting in better product quality and consistency.

Future Trends in Custom Spare Parts Manufacturing

As manufacturing technology continues to advance, the production of custom spare parts is becoming even more efficient and accessible. Some future trends include:

- On-Site 3D Printing: With the development of portable 3D printers capable of working with metals and advanced composites, it is becoming possible to produce spare parts directly on-site, further reducing downtime.

- AI-Driven Design Optimization: Artificial intelligence can analyze machinery performance data and suggest design improvements for custom parts, ensuring that replacements are optimized for performance and durability.

- Blockchain for Supply Chain Security: Blockchain technology can be used to create a secure digital record of custom parts, ensuring traceability and preventing counterfeiting, which is critical for industries like aerospace and defense.

Conclusion

Custom spare parts are an essential component of maintaining and optimizing specialized machinery. Their ability to meet precise specifications ensures compatibility, extends the life of equipment, and reduces the costs associated with downtime. Although producing these parts presents challenges, advancements in additive manufacturing, reverse engineering, and digital twins are making custom spare parts more accessible than ever. By investing in these technologies, manufacturers can ensure that they are ready to meet the demands of modern industrial operations, keeping their machinery running smoothly and efficiently.

4Ever Machinery is committed to providing top-tier custom spare parts production for specialized machinery. With expertise in advanced manufacturing techniques and a focus on quality and precision, we offer solutions that keep your operations running with minimal disruption and maximum efficiency.